Completed - 2000 to 2009

Welkom Industrial Controls have completed projects since 1988. Never has a project not been completed from our

side. We are a committed team. The following is a list of high-lighted projects that we have done over the last 10 years.

This project consisted of new PLC programs for the plant on surface and the storage areas underground. Modicon TSX

Quantum PLC’s were used with Magelis HMI’s. New DFB’s for the electrical motors (drives) and valves were developed

to control the process and to create a standard for control devices for concept programming software.

Bambanani Mine Backfilling Plant - April 2006

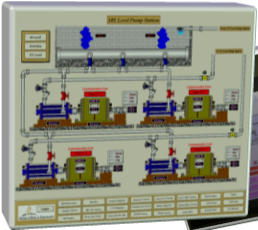

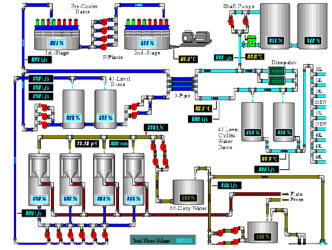

There are 20 pumps at the mine that are distributed on the three shafts of the mine, main, sub and a 3rd shaft. Most of the

pumps have synchronized electrical motors. Only on the bottom pump station, there are induction motor pumps. The

old electrical control was removed and a new PLC control was implemented. A new control panel, field junction boxes

and instrumentation were supplied. The excising Wonderware SCADA was upgraded and all the pump information was

added on the SCADA. The pre-start, current and historical information was added to the SCADA, by implementing a

Wonderware Industrial Server on the system.

DSM Pumping Project for Tau Tona Mine - April 2006

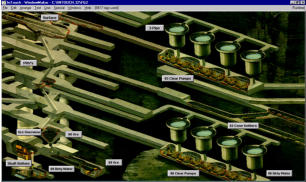

This was an upgrade from multiple Wonderware Intouch SCADA nodes to an ArchestrA system. Objects and standards

were developed for the new way of thinking. These were the building blocks of the ArchestrA system. All the graphics were

re-linked to the new objects. TOP server drivers with OPC were used to communicate to the Allen-Bradley PLC’s. At that

point of time the mine had +- 30 PLC underground and on surface. These PLC’s were used to control ore-loading,

compressors, fridge plants, bulk air coolers, pump stations, 3-pipe systems, monitor and control water and air usage. We

decided to use the old reporting system. This system was developed in 1995 with Excel to connect to the InSQL server,

retrieve information and publish information on a web server every morning at 05h00. This was before Wonderware

had developed Active Factory. Wonderware was very interested in this design. Not long after that, the first

Active Factory was launched.

Tshepong Wonderware Upgrade - August 2006

We were asked to upgrade the generator system on synchronous motors to a static excitation system. These 11kV

motors were used on water pumps. Some of them were still on manual excitation. The pump attendant started the motor

with a closed valve and then manually adjusted the generator field current. The generator current was changed and fed into

the synchronous motors to get the power factor to unity. The other pumps have field controllers on the generator to

control the power factor. Welkom Industrial Controls has decided on a Siemens DC Drive, the Simoreg for the control

The internal PID controller of the Simoreg was used. We decided to use a reactive energy transducer

and not a power factor transducer. The electrical motors were more then a megawatt big and there was potential to save by

controlling the reactive energy in the motor, from starting, opening the delivery valve, pumping and shutting of

the pump. These controls were interfaced into the existing PLC’s, that WIC had already installed during a previous

project.

Static Excitation - October 2006

A new level was added on the mine and we won the tender to add PLC controls on the new pumps. We used

our existing design for pumps and built new pump panels for the mine. The size was 1.5 MW induction

motors. Automatic delivery valve control with start and stop sequence. We used Momentum PLC’s with Magelis

HMI’s. The information was added to the mine exciting SCADA system.

97 Level Pump Station - December 2006

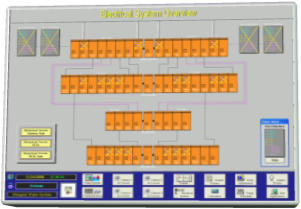

This project consists of seven compressors from +- 2MW to 4.5MV that needed to be upgraded from very old controls

to new. Quantum PLC’s were used for the logic controllers with Magelis HMI’s. The LT motor controllers used were

TeSysU with modbus communication. Multiple EGX’s modbus TCP/IP gateway were used to improve communication

between the PLC and the motor controllers. All the compressor motors were synchronous motors. A BR-1000 controller

was used to control the excitation on the motor. The PLC was interfaced to a reactive transducer. The pressure control

was done by a master controller (Momentum PLC). Moore Controller was used to protect the compressor against

anti-surge. Five compressors sited on one mine and the other two on a mine +- 5km further away. An ArchestrA SCADA

system was implemented to control and monitor the whole system.

DSM Compressor Upgrade Wes-Wits - March 2007

This is a mine situated close the Stilfontein. This shaft pumps water out of the mines to control underground water

levels. A DSM project was launched to save electricity. Welkom Industrial Controls was asked to do the project.

Momentum PLC’s with Magelis HMI’s were used to control the pumps on the two levels. A Wonderware Intouch

SCADA was added to the system. The MV motor starters, fibre communication and control on the pumps were all

new equipment on the protect. New instrumentation, control valves and junction boxes were installed.

DSM Pumping Maragret Shaft - April 2007

A project was launched to do energy savings on Tsepong Mine Fridge Plants. The controls and piping of the plants

were modified to improve cooling down of water in the off-peak times. Allen-Bradley PLC’s were used and the new

PLC information was added to the existing SCADA system. From the SCADA, the control valves set-point can be

manipulated for the best cooling down of water, before the water goes down the mine shaft.

DSM Fridge Plants - June 2007

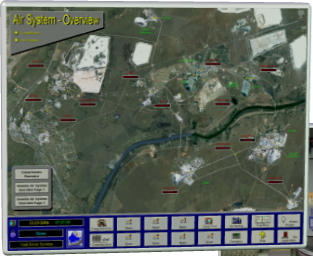

This project consisted of five compressors on three different mines. The sizes of the compressors vary from 2 MW to

4.5MW. Quantum PLC’s were used with Magelis HMI’s. Welkom Industrial Controls has a very robust compressor

design that works. The same designs and equipment were used for these upgrades. Air stations, with mass flow

equipment, were added to the system for billing purposes. These air stations were on a remote radio telemetry system.

PID controllers in momentum PLC’s were used to control the down-stream air pressures. All the information of the

compressors and remote air stations was brought back to a control room, via fibre fibre optics, radio-LAN and

remote telemetry.

DSM Compressor Upgrade Vaal River - October 2007

An air optimization project was awarded to Welkom Industrial Controls to help with a DSM energy project. Air control

valves were installed underground to reduce air flow and pressures. The result was that the usage of compressed air

was reduced and the compressors started to cut-back and save electrical energy. Momentum PLC’s were used exclusively to

control these valves. The system was connected to an ArchestrA SCADA system. The ArchestrA system was installed

on a previous project on these mines. The air flows, pressures and control position were added to the SCADA.

Beatrix Air System - November 2007

Welkom Industrial Control has proven that we are knowledgeable on big water pumps and this project was awarded to us to

do the instrumentation and control on the new pump station. Again we have standardised on a well proven design. Schneider

Electric PLC’s and HMI’s were used for the project. The pump information was later added to the excising SCADA of

the mine. The complete project which included, instrumentation supply, installation, all cable work, software and commissioning,

was done by us.

Pump Station 116 Level - March 2008

This is the biggest air compressor that Welkom Industrial has worked on. Thanks goes to the company that awarded

this job to us. It was a privilege. This compressor motor was an induction motor, thus no excitation control was needed.

The TeSysT motor starters were used in the design. WIC developed a very comprehensive design around the TeSysT

motor starters from Schneider Electric. This model was implemented. The anti-surge protection was done with a Moore

Controller. The information was also added to the existing ArchestrA system, which was originally done by Welkom

Industrial Controls.

DEMAG 10.3 MW Compressor - March 2009

Old pump controls have been upgraded to new static excitation control. Again we used the Siemens Simoreg drives

for the job. New Momentum PLC’s, instrumentation, delivery valve and junction boxes were installed. The MV

protection used Micom P241 relays.

Savuka Pumps 83 Level - August 2009

The surface fridge plant was upgraded from elect-mechanical controls to PLC’s. S7 Siemens PLC’s were used for the

controls. All the instrumentation, cables and control panels were replaced. New S7 software was develop for the

control of the plants. The plant was stopped between 18h00 and 20h00 to save electrical energy.

DSM Kopanang Gold Mine Fridge Plant Upgrade - June 2005

Welkom Industrial Controls has developed a lamp room system can record CO and methane test from various

instrument suppliers. These test results, issuing of equipment, repair and maintenance are stored in a Microsoft SQL

database. The information can be viewed via web interface pages.

Lamproom System Tshepong Mine - August 2003

This project was a DSM saving project. Pump stations at Beatrix 1,2 and 3 shaft were upgraded with PLC controls. New

instrumentation, cables, control panels were supplied and installed. A fibre backbone was also installed in some of the

mine shafts. All of the pump information was added on the mine existing Wonderware SCADA system.

DSM Beatrix Pumping System - March 2003

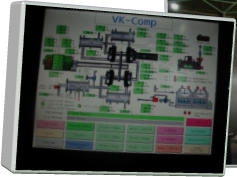

A Sulzer compressor was upgraded from electro mechanical controls to a PLC system. A Quantum PLC with

Concept programming software was used. The HMI was a Wonderware Intouch computer system. The existing

instrumentation and junction boxes were used. All the instrument loops were re-checked and commissioned.

Sulzer RIK 56 Compressor Upgrade - April 2000

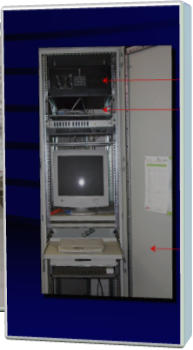

The supply, installation and programming of Control Logix 5550 processors, as well as setting up of communications

to the existing PLC network underground and SCADA.

Tshepong Control Room PLC Upgrade - January 2001

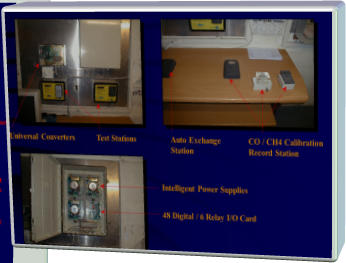

The development of Lamproom CO and methane test stations. This system was part of the asset management and

tracking system and was streamlined for mine Lamproom management. The system uses ActiveX web technology to

assign and allocate equipment to users. Faulty equipment can be de-allocated and a spare unit can be assigned to the

user. The hart of the system is Microsoft SQL database. Reports can be retrieved via web ASP technology.

Lamproom Test Stations - January 2002

Welkom Industrial Controls has supplied and installed a big CCTV camera system for the mine. All cameras

were recorded with DVR technology.

Hotazel Manganese Mines (Samamcor) - January 2004

Supply, delivery, installation and commissioning of a total control system for 70 level locomotive (Big Mama). This project

consisted of two electrical loco’s with an overhead 500VAC line. This loco is used to tram ore from loading areas to the

trips. Electrical rail switches, robots and a tracking system was Welkom Industrials’ responsibility. A MRS leaky feeder

system was installed to retrieve information from the train. This system was later upgraded to a radio-LAN system for

better and faster communication, Siemens access points were used.

Project Katleho - March 2004

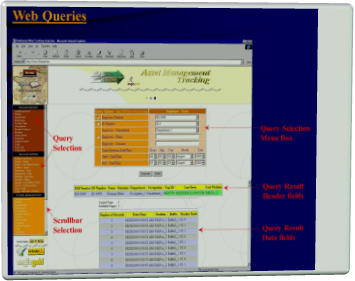

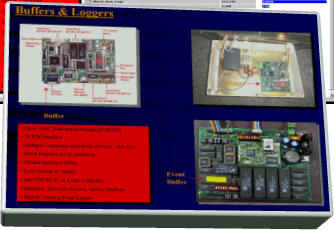

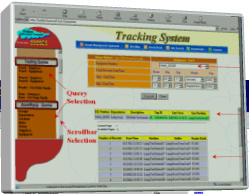

Welkom Industrial Controls has developed a SQL database for asset management. The main database components

are employees, equipment and tags. Multiple pieces of equipment can be allocated to employees. This equipment can

be assigned, de-assigned, repaired, calibrated, etc. Each piece of equipment can be allocated to multiple types of tags,

active, passive or bar-coded. These equipment can then be tracked with various types of tag readers across the company. All the

information is data/time stamped and stored in ethernet buffers and then uploaded into the SQL database with a positive

acknowledge system. The information from the database can be queried via web or in SCADA systems with custom

ActiveX objects. Live graphic animation objects were also available.

Asset Management & Tracking System - June 2003

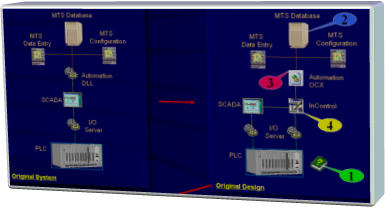

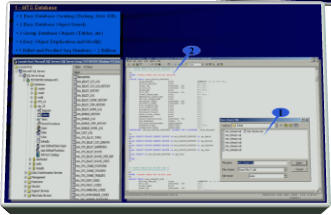

Welkom Industrial Controls was asked to re-do the MTS system that was original developed by a Norwegian

company. The complete SQL database tables, store procedures, views and triggers were re-written. The user

interface software was developed in VB6. The interface between the plant Quantum PLC and the SQL database

was a Wonderware InControl soft PLC. This project was done in the area between Richards Bay and Welkom,

in the Drakensberg region. Every month, for a year, some of the software guys of Bayside and us worked two weeks

at a time, to back engineer and re-code everything. This project was a huge success and implementation was

done in a two week stretch.

Material Tracking System (MTS) Bayside Smelter - August 2003

Welkom Industrial Controls was contacted to develop a new winder simulator from an old design. The

old system was a computer based system written in Pastel for Dos. We back engineered the system and with

the help of personnel from Anglo Gold and Platinum training centres, we developed a new system and added a lot

of new functionality to it. We used VB6 software with new electronic hardware cards, developed by us, to

do the job. Afterwards Anglo Platinum asked us to add additional functionality to the system for them.

Winder Simulator - November 2006